Note: Once

finished, models shouldn’t be used as toys in the commercial

sense of the word. They are an educational tool, suitable

for the classroom

1.) Technical Information

Activities to be undertaken

Required tools (not included in the

kit)

1.3 Measurements

600x320x150mm

1.4 Objective

The construction of the bridge will allow the students to

learn how to resolve two problems-How to ensure the safe

passage of people and vehicles over the bridge-How to equip

the bridge to allow the passage of boats taller than the

bridge

2.1. Material provided

| Material | Number | Measurements | Piece | Picture |

Plywood |

1 | 10x140x498 mm | Base |  |

| 2 Pine strip | 1 | 10x50x300 | 2x10x50x1002x10x50x50 | |

| 3 Pine strip | 4 | 10x75x80 | ||

| 4 Pine strip | 1 | 10x50x350 | ||

| 5 Plywood | 1 | 5x70x250 | 1x5x70x601x5x70x1102x5x10x45 | |

| 6 Pine strip | 4 | 10x15x325 | 1x10x15x3101x10x15x3001x10x15x160

1x10x15x150 2x10x15x90 3x10x15x40 |

|

| 7 Wooden Pulley | 2 | Ø10×10 mm | ||

| 8 Pine strip | 3 | 5x10x250 | 1x5x10x1151x5x10x903x5x10x80

1x5x10x70 1x5x10x20 3x5x10x15 |

|

| 9 Rods | 12 | Ø3×500 mm | ||

| 10 Cotton thread | 1 | 2 meters | ||

| 11 Metal rod | 1 | Ø3×95 mm | ||

| 12 Retention rings | 6 | Ø3 | ||

| 13 Metal rods | 2 | Ø3 x 70 mm | ||

| 14 Mounting blocks | 2 | 30×53 mm | ||

| 15 PVC fittings | 2 | Ø7 x 25 mm |

Reducing motor | |

| 16 Brass fitting | 1 | Ø4 x 25 mm |

Reducing motor | |

| 17 Motor | 1 | Ø21 x 25 mm |

||

| 18 Double toothed wheel | 4 | 50/10 teeth | 3 whites, 1 red |

2.2 Material provided

| Material | Number | Measurements | Picture |

| 19 Pinion | 1 | 10 teeth |  |

| 20 strips connections | 2 | 12 connections | |

| 21 LED | 2 | Ø 5mm red |

|

| 22 LED | 2 | Ø 5 mm green |

|

| 23 Resistors | 2 | 130 Ω |

|

| 24 Limit switches | 2 | 250 V/5A | |

| 25 Sliding switch | 1 | 6 contacts | |

| 27 Electric wire | 1 | 10 m | |

| 28 screw bolt | 2 | M4 x 30 mm | |

| 29 Nut | 4 | M4 | |

| 30 Washer | 6 | M6 | |

| 31 screw bolt | 2 | M3 x 35 mm | |

| 32 screw bolt | 1 | M3 x 20 mm | |

| 33 Nuts | 4 | M3 | |

| 34 Washer | 8 | M3 | |

| 35 eyebolt | 4 | Ø 3 x 10 mm | |

| 36 Screws | 6 | DIN 7981 | |

| 37 Screw | 8 | DIN 96 | |

| 38 Screw | 2 | DIN 7981 | |

| 39 Battery holder | 1 | 2 (1,5 V) battery | |

| 40 Battery holder connector | 1 |

3. Construction

Before starting to make the bridge it is important to

familiarise yourself with the general plans of the bridge

(figures 27/28) and the diagram of the electrical layout.

Construction phases

3.1. The construction of the moving section of the bridge

3.2 The construction of the bridge

pillars3.3 The construction of the barrier3.4 The

construction of the reduction motor3.5 The assembly of the

different components3.6 Electrical installation

3.1 The construction of the the moving

section of the bridge

3.1.1 Cut two 80 x 50 x 10 mm pieces and two 50 x 50 x 10

mm pieces of wood from the piece of wood measuring 300 x 50

x 10 mm (2), using a saw. The two pieces 80 x 50 x 10 mm are

going to be used for the bridge pillars

3.1.2 Mark the centre of the two 50 x 50 x10 mm pieces,

obtained in point 3.1.1, and round them off as shown in

figure 2. These pieces will serve as the base for the moving

section of the bridge.

3.1.3 Drill a hole through the two pieces at the same,

using a Ø3mm drill piece, at the

point indicated in figure 2.

Note: Put the pieces on on top of the other, fix

them together with adhesive tape and drill both holes at the

same time. The Ø 3 x 95 mm shaft

(11) will be passed through this hole later. 3.1.4 Make a

2.5mm wide and 55mm long groove in both sides of the 10 x 50

x 350 mm strip of wood (4), as shown in figure 3.

3.1.5 Glue the two perforated 50 x 50 x10 mm pieces onto the

walkway piece of the bridge (4), as shown in figure 3. 3.1.6

Cut the following pieces, indicated in figure 4, from the

two large pieces (8) of 500 x 10 x 5 mm. 1 piece of 115 x 10

x 5 mm 1 piece of 90 x 10 x 5 mm 3 pieces of 80 x 10 x 5 mm

1 piece of 70 x 10 x 5 mm 3 pieces of 15 x 10 x 5 mm

3.1.7 Make a slit, 1mm wide and 5mm long, in both ends of

the 115 x 10 x 5 mm piece of wood (obtained in point 3.1.6),

as shown in figure 5.

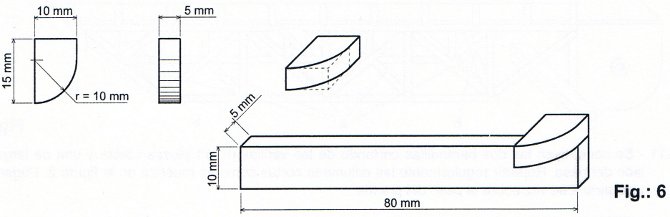

3.1.8 Make a piece like the one shown in figure 6 from

one of the 15 x 10 x 5 mm pieces (obtained in point 3.1.6).

Then glue this piece to the end of a 80 x10 x 5 mm piece of

wood (from point 3.1.6) in the position indicated in figure

6.

3.1.9 Stick the 115 x 10 x 5 mm piece from point 3.1.7,

with the the piece of 80 x 10 x 5 mm, obtained in point

3.1.8, and the 80 x 10 x 5 mm strips onto the walkway of the

bridge, as shown in figure 7. Fix an M4 washer (30) to the

outside face, over the hole, as shown in figure 7.

3.1.10 Make the frame and rails of the walkway of the bridge

using the rods (9) and the template in figure 29, on the

scale 1:1. Make one side first, then the other and glue them

to the underside of the walkway. Then fix the crossbeams (a)

between both frames and the diagonals (b) to each end

triangulating the end of the structures, as shown in figure

8.

3.1.11 Make the two rails by cutting eleven short pieces

and one long piece for each side from the rod (9). Space the

short rods equally, as shown in figure 8. Stick the whole

together and glue to the bridge. Note: Assure

yourself that neither the frame nor the rails exceed the

limits defined in figure 8 as this could cause problems with

the raising and lowering of the bridge.

3.2 The construction of the bridge

supports

3.2.1 With care, cut out a hole in one of the 80 x 75 x

10 mm pieces with a coping saw, as shown in figure 9. This

is where the sliding switch will be placed later, to connect

and disconnect the current. Take a second 80 x 75 x10 mm

piece and bevel the corners of both pieces at the angle

shown and make a hole in the same position in both with a

3mm drill, as shown in figure 9.

Note: Put the two pieces one on top of the other,

join them together with adhesive tape and do the beveling

and perforating in both at the same time.

3.2.2 Stick the two large 80 x 75 x 10 mm pieces with the

Ø 10 mm pieces obtained in point 3.1.1, as shown in figure 10.

Do the same with the two 80 x 75 x 10 mm pieces without

holes and another 75 x 50 x 10 mm piece.

3.2.3 Stick the first piece (the one with holes),

obtained in point 3.2.2, to the large 495 x 140 x 10 mm (1)

piece, to act as a bridge support, as shown in figure 11.

3.2.4 Place the moving part of the bridge (from point 3.1)

between the two bridge supports and fix them in place using

the Ø 3 x 95mm metal shaft (11).

Make sure it can move. On the right, the board must be a

little lower than the horizontal. If necessary, file the

support down a little at the points where it supports the

walkway of the bridge. See figure 12. Fix the rod in place

with the washer (12). See figure 12 Attach the second

support (without holes) to the end of the base. Make sure

there is a gap of 0.5 and 1 mm between the support and the

walkway.

Dictionary:::

pillars: vertical support; a column